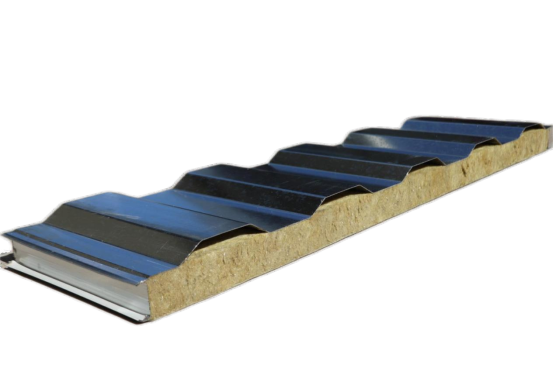

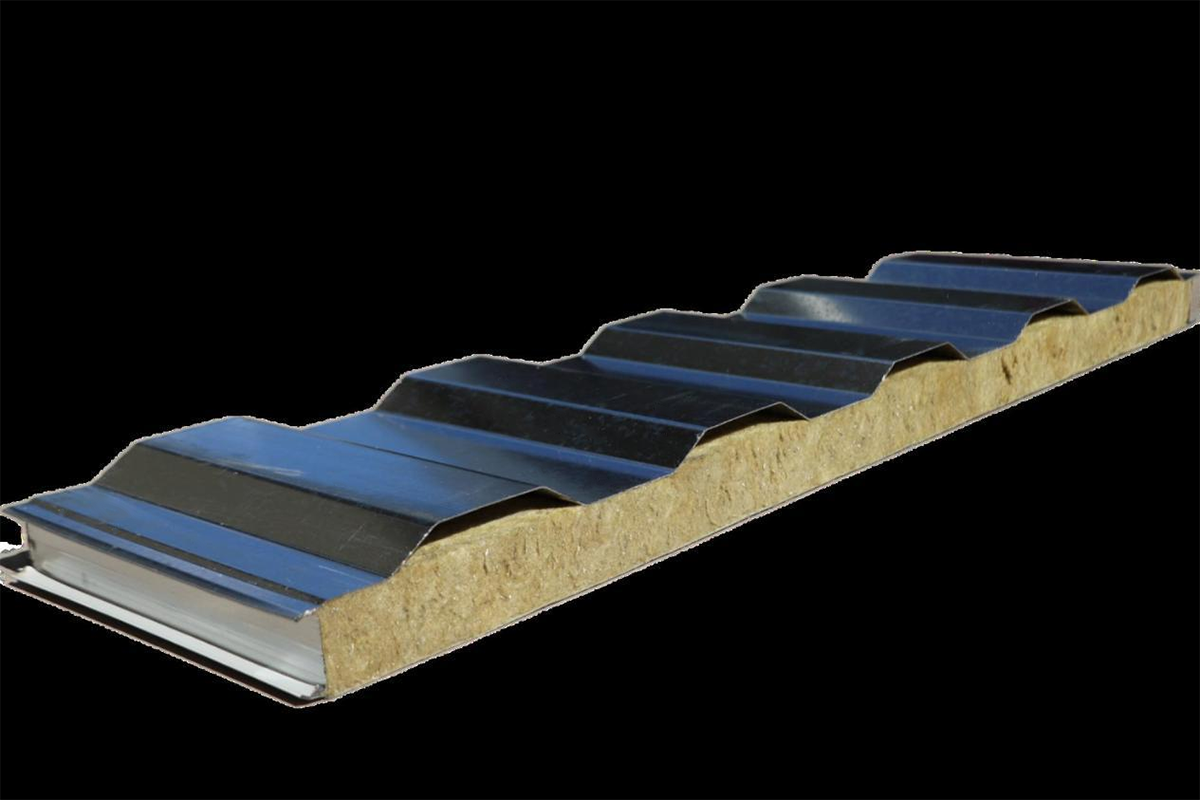

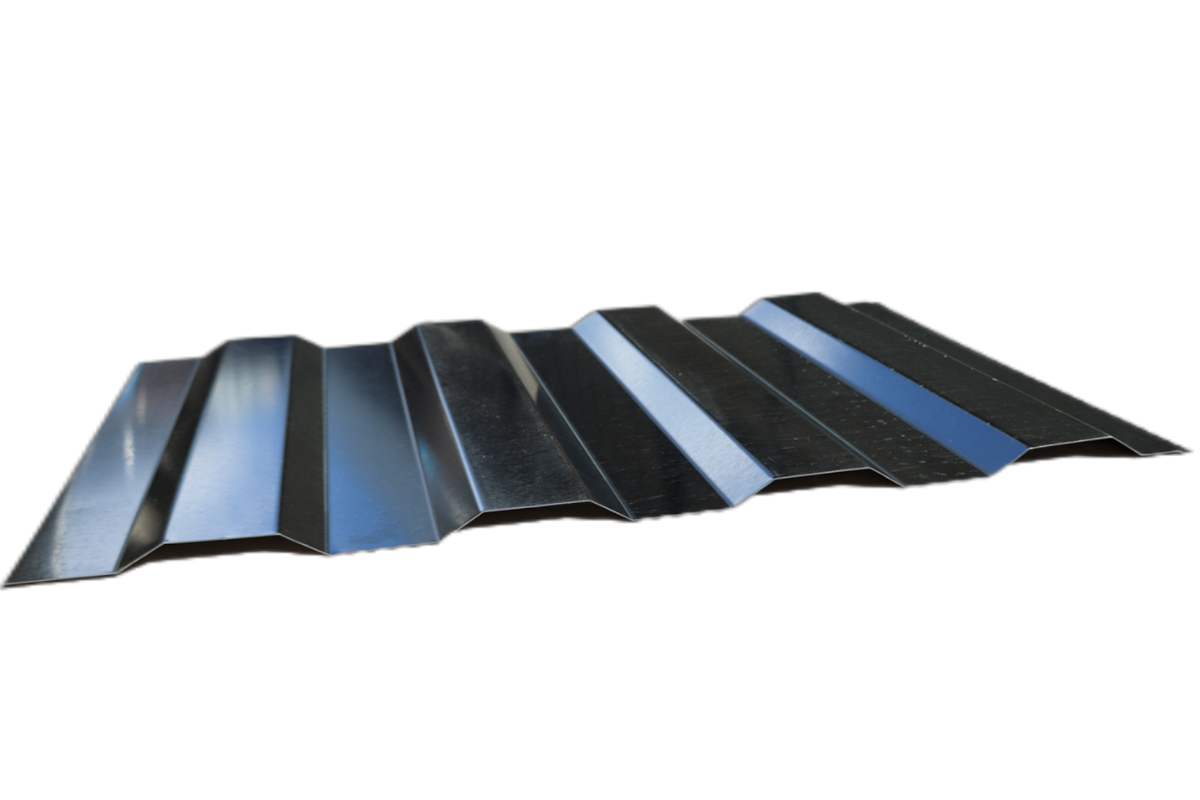

1. Upper surface: Galvanized coils with a thickness of 0.4-1.0mm are commonly used. According to the specific requirements of the customer, color coated rolls can also be used.

2. Lower surface: Color coated roll with a thickness of 0.2-0.8mm.

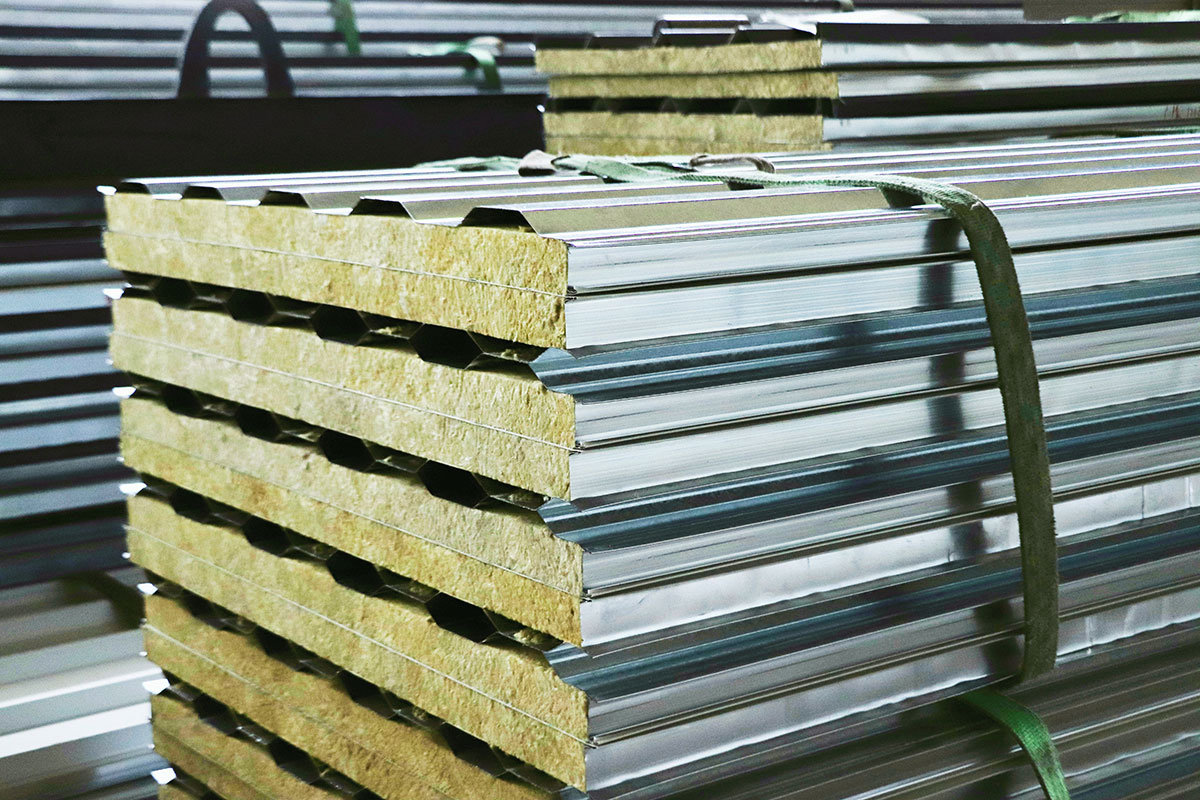

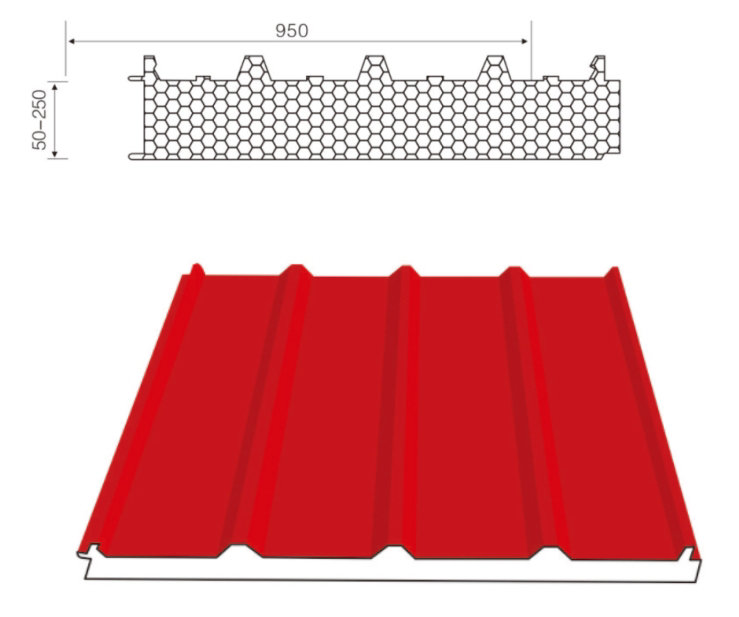

3. Core material: 50-250mm rock wool, white foam, real gold foam, density can be customized.

4. Length: Customized length

5. Model (effective width): 1135 type

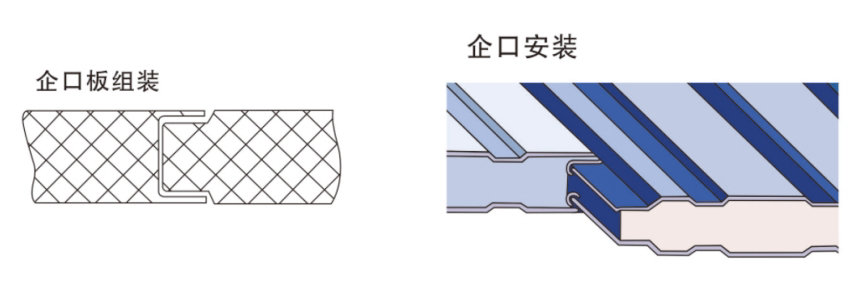

6. Installation method: Enterprise mouth installation

※ Detailed explanation of core material:

Rock wool

It is mainly made of basalt as the main raw material, melted at high temperature, and made into inorganic fibers by high-speed centrifugal equipment. At the same time, a certain proportion of adhesive is uniformly added and baked into large boards, which are cut into rock wool strips according to production needs. Rock wool is a non combustible material with good fire resistance.

Real gold foam

The polymer fireproof isolation compartment particle technology is applied, which forms a continuous honeycomb structure with thermal insulation when encountering flames, blocking flame penetration and achieving a "quasi non combustible" fireproof effect. It has good compressive strength, impact resistance and stability, water resistance, moisture resistance, freeze-thaw resistance, and impermeability. The material is environmentally friendly, with no harmful substances evaporating, and does not decompose or mold.

White foam

The foamed plastic sheet with micro closed cell structure is made of expandable polystyrene (EPS) particles as raw materials, shaped like fertilizer particles, heated and pre foamed into large white pearl like particles, and then heated and pressed in the mold. Due to poor fire resistance, it is mostly used for temporary buildings.

Purpose:

Can be used on the side of containers, container houses, container truck decks, mechanical equipment boxes, and can also be used as the roof of container houses.

Overlapping method:

Online Service

Online Service