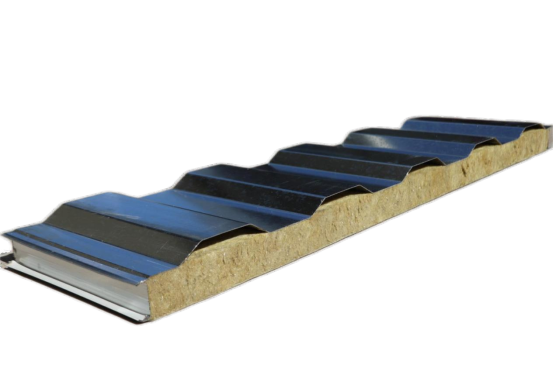

Dianchang metal sandwich composite board is made of high-quality color coated steel plate or other precision profiled metal plate panel and high-quality rock wool/foam core material, which has excellent characteristics of fire prevention, thermal insulation, environmental protection, etc. There are currently three composite panel production lines (2 Changxing and 1 Xusheng) in the Dianchang composite panel workshop. The first Changxing production line can produce composite panels, the second Changxing production line can produce composite panels and composite tiles, and the Xusheng production line can produce composite panels, composite tiles, and large corrugated container panels.

1、 Metal sandwich composite wall panel

Characteristic:

1. Good insulation performance: Rock wool, as a sandwich material, has good insulation and thermal insulation properties, which can effectively reduce the conduction of heat.

2. Good fire resistance: Rock wool has a high fire resistance temperature and good fire resistance, which helps to improve the fire rating of buildings.

3. Significant sound absorption and insulation effect: Rock wool sandwich panels have a significant reduction effect on noise transmission.

4. High compressive strength: Color steel plate, as the outer material, has good compressive performance and can withstand certain pressure and load.

5. Good corrosion resistance: The surface of the color steel plate has been specially treated to resist corrosion and oxidation, and has a long service life.

6. Convenient construction: Compared to traditional building materials, color steel rock wool sandwich panels are lightweight and easy to transport and install. Due to the absence of secondary processing on site, the installation cycle of the composite board is greatly shortened, and the daily average installation area of the composite board reaches 600-800 square meters.

Construction:

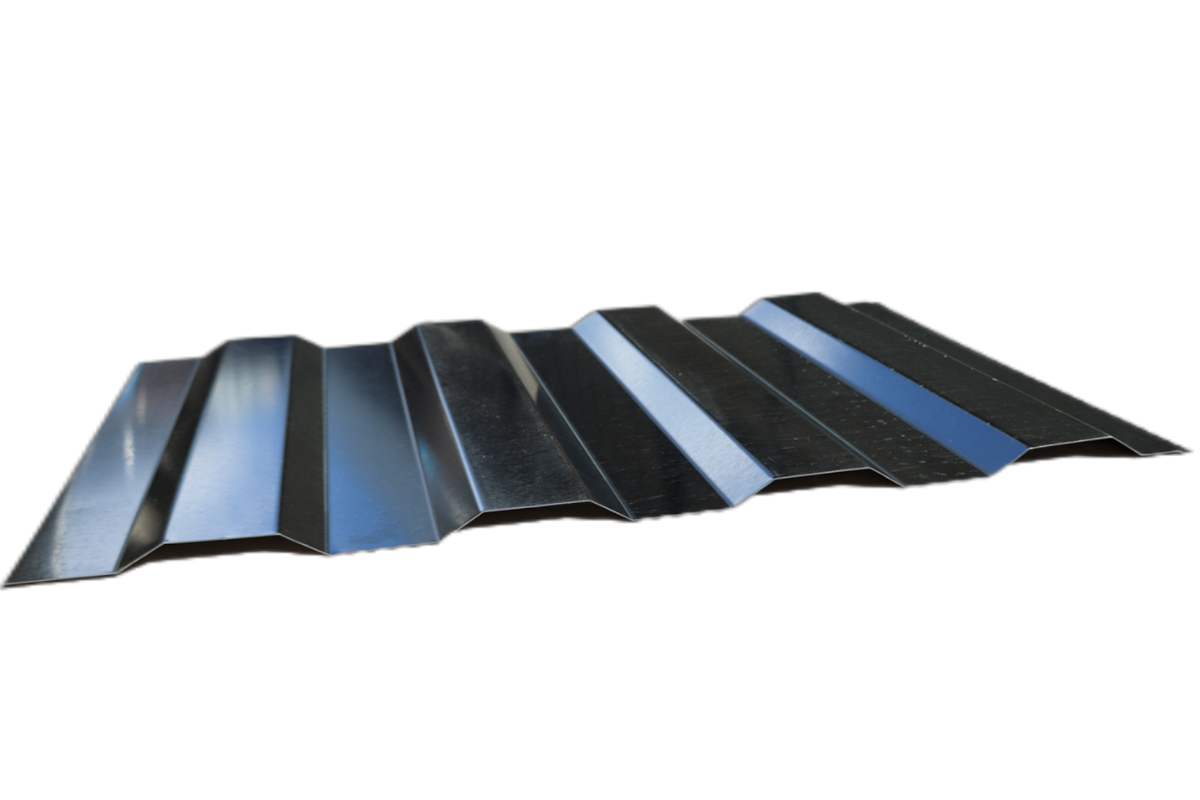

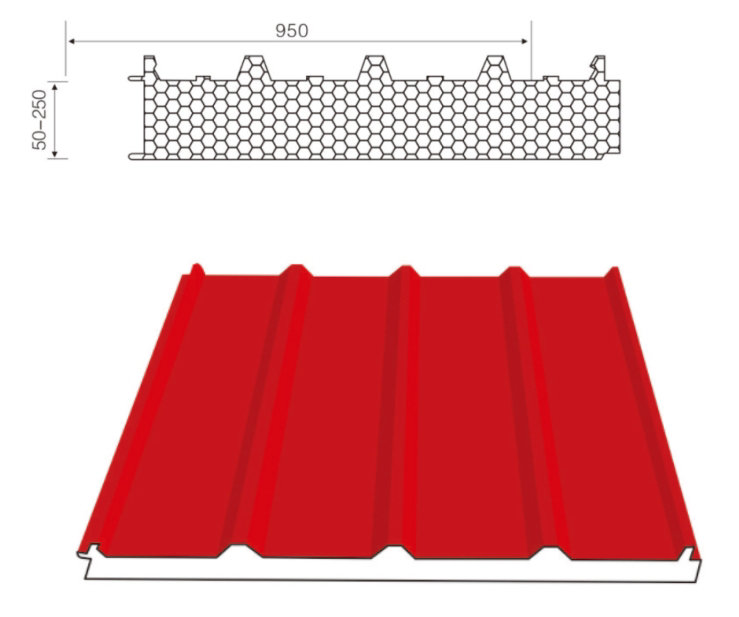

1. Upper and lower surfaces: using color coated rolls with a thickness of 0.2-0.8mm. According to the specific requirements of the customer, aluminum coils, PVC or galvanized steel plates can also be used.

2. Core material: 50-250mm rock wool, white foam, real gold foam, density can be customized.

3. Length: Customized length

4. Model (effective width): 950, 1150

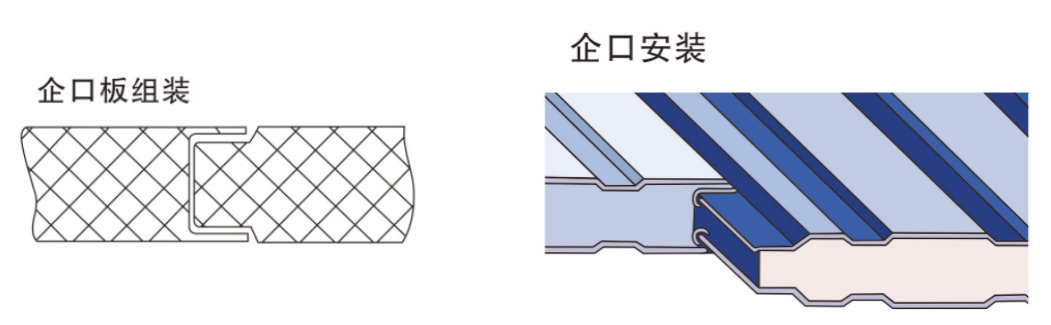

5. Installation method: Enterprise mouth installation

※ Detailed explanation of core material:

Rock wool

It is mainly made of basalt as the main raw material, melted at high temperature, and made into inorganic fibers by high-speed centrifugal equipment. At the same time, a certain proportion of adhesive is uniformly added and baked into large boards, which are cut into rock wool strips according to production needs. Rock wool is a non combustible material with good fire resistance.

Real gold foam

The polymer fireproof isolation compartment particle technology is applied, which forms a continuous honeycomb structure with thermal insulation when encountering flames, blocking flame penetration and achieving a "quasi non combustible" fireproof effect. It has good compressive strength, impact resistance and stability, water resistance, moisture resistance, freeze-thaw resistance, and impermeability. The material is environmentally friendly, with no harmful substances evaporating, and does not decompose or mold.

White foam

The foamed plastic sheet with micro closed cell structure is made of expandable polystyrene (EPS) particles as raw materials, shaped like fertilizer particles, heated and pre foamed into large white pearl like particles, and then heated and pressed in the mold. Due to poor fire resistance, it is mostly used for temporary buildings.

Purpose:

1. Industrial buildings: applicable to the walls of industrial buildings such as factories, warehouses, workshops, etc.

2. Logistics Park: Suitable for storage and transportation in logistics transfer centers on buildings.

3. Commercial buildings: suitable for exterior wall decoration of commercial complexes, shopping malls, supermarkets, exhibition halls, and other buildings.

4. Office building: Suitable for the exterior walls and partitions of office buildings and other buildings.

Overlapping method:

Online Service

Online Service