Also known as steel plate waterstop. Because in box foundations or basements, the concrete for the bottom, exterior, and top panels is poured and compacted separately, the next time the concrete for the wall panels is poured and compacted, there will be a construction cold joint. When this joint is located below the groundwater level, it is easy to cause water seepage. This requires technical treatment of this seam, and there are many methods of treatment, among which the most common method is to install a waterproof steel plate.

Usage method:

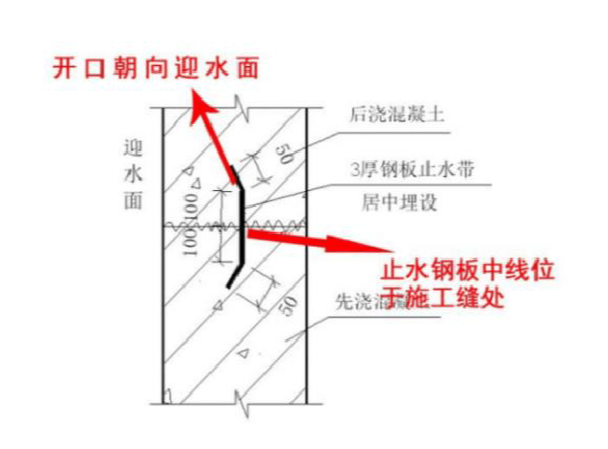

When pouring the lower layer of concrete, pre embed steel plates, with 10-15cm of the upper part exposed to the outside. When pouring concrete again next time, pour these steel plates together to prevent the infiltration of external pressure water. Therefore, the waterproof steel plate has high requirements for welding nodes, and there should be no leakage points that affect the waterproof performance (as shown in the conceptual diagram).

Key points of construction:

1. Efforts should be made to ensure that the waterproof steel plate is on the centerline of the wall;

2. The welding between two steel plates should be full and double-sided, with a minimum overlap of 20mm between the plates;

3. The treatment at the corner of the wall includes bending the entire steel plate; 2、 T-shaped welding; 3、 7-shaped welding.

4. The support welding of the water stop steel plate can be spot welded onto the main reinforcement with small steel bars;

5. When the waterproof steel plate passes through the column hoop reinforcement, the hoop reinforcement can be disconnected and made into an open hoop, which is welded onto the steel plate.

6. The "opening" of the waterproof steel plate faces the upstream surface.

Online Service

Online Service