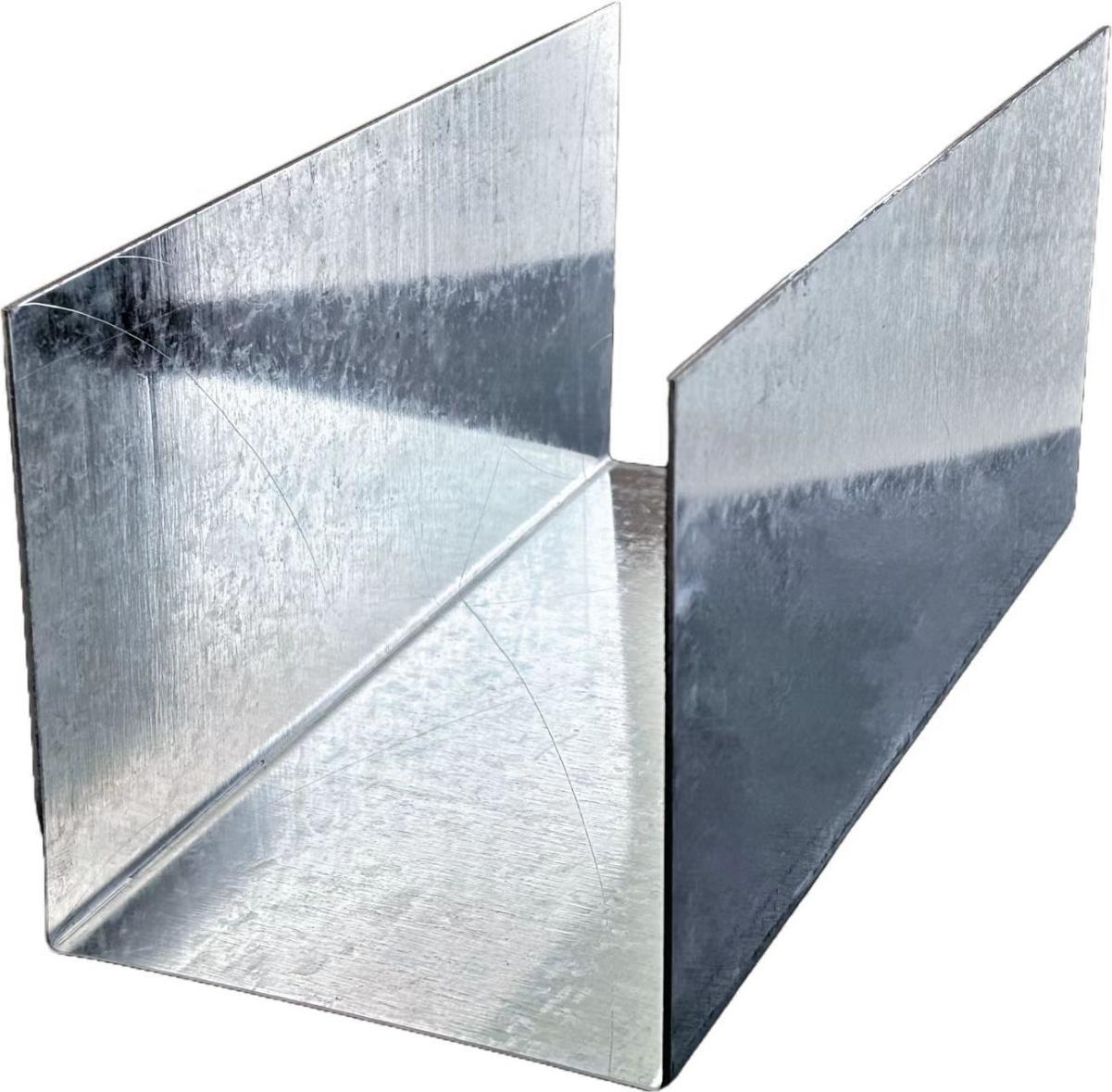

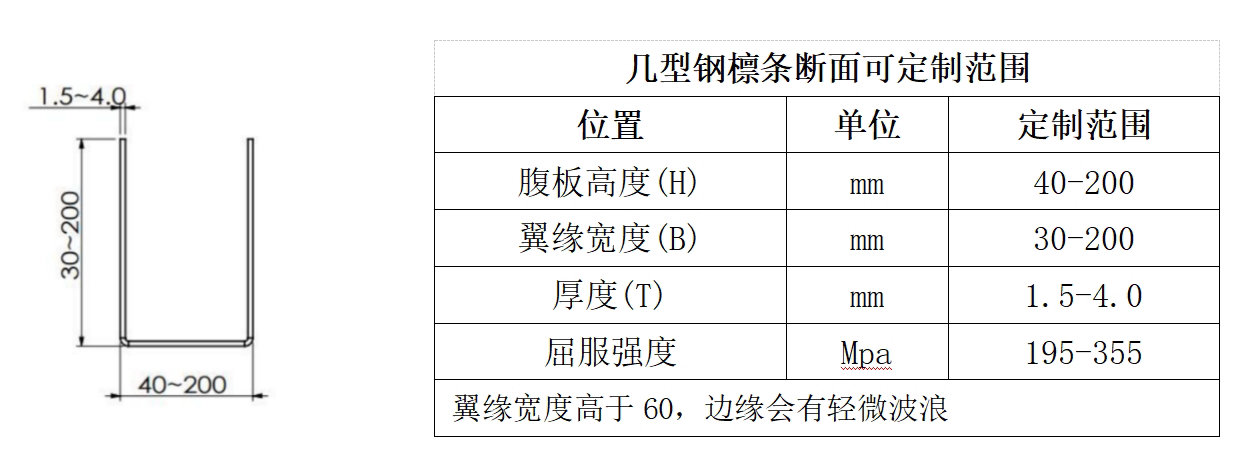

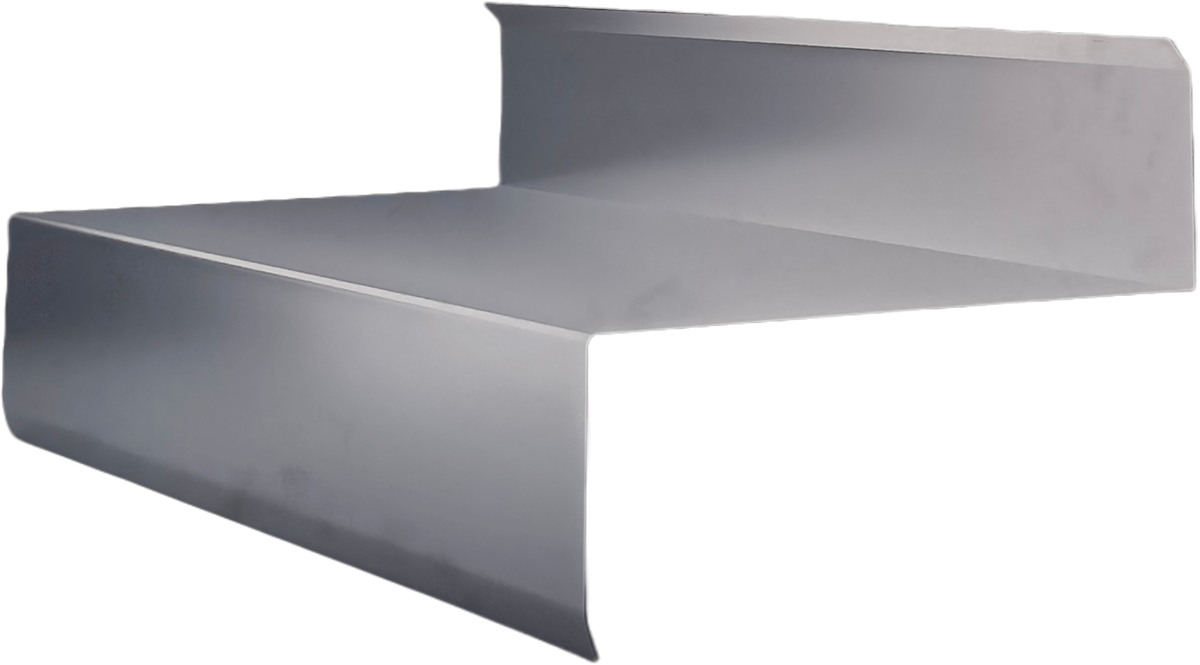

U-shaped purlin is a steel material shaped like the letter U. Has the following characteristics:

1. Good stability: U-shaped purlins have a large moment of inertia, can withstand large bending forces and torques, and provide good support and stability.

2. Uniform pressure distribution: Both sides of the U-shaped purlin are right angles, which can better distribute pressure, reduce local stress concentration, and improve the service life of the component.

3. Easy installation: U-shaped purlins are commonly used to connect and reinforce metal components, such as steel columns and beams. They can be fixed by bolts or welding, and the installation process is simple and fast.

The application range of U-shaped purlins is also very wide, commonly used for:

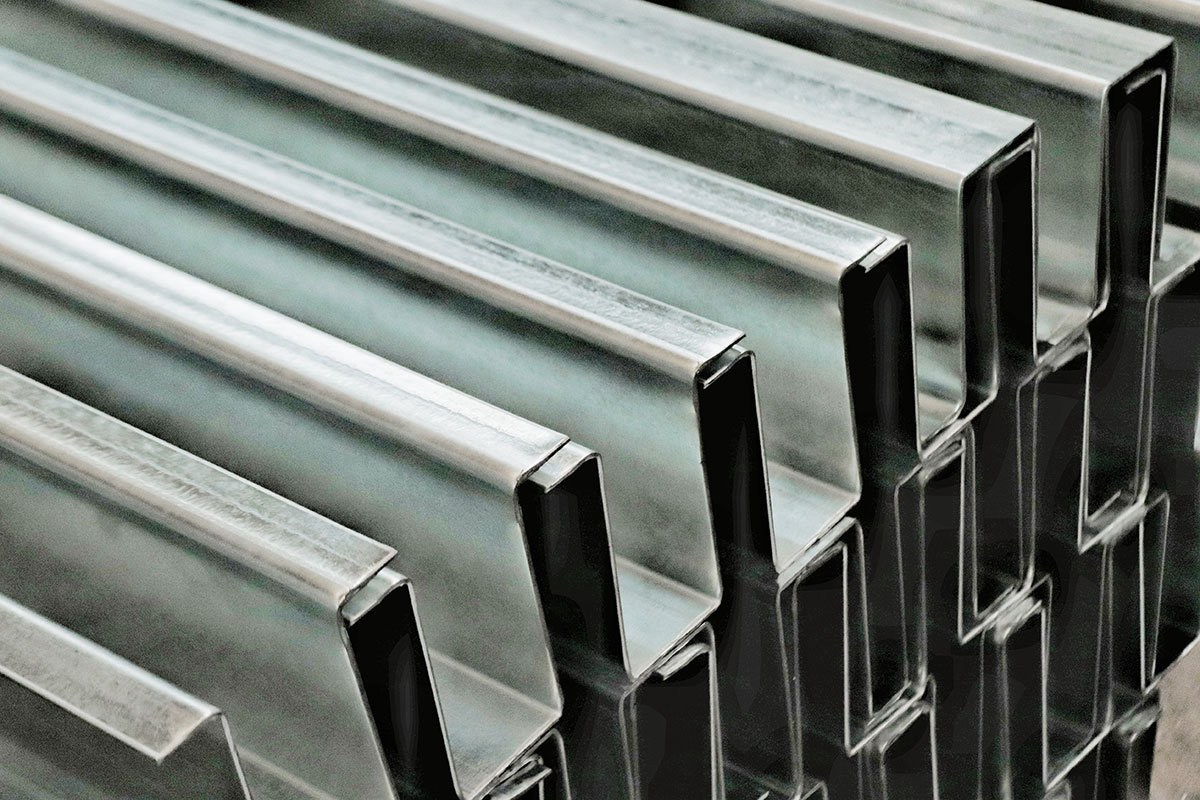

1. Steel structure buildings: U-shaped purlins are commonly used for connecting and reinforcing columns and beams in steel structure buildings. They can effectively improve the overall stability and seismic resistance of buildings.

2. Bridge engineering: U-shaped purlins can be used for bridge support and reinforcement in bridge engineering. They can withstand the horizontal and vertical forces of the bridge, ensuring its safe operation.

3. Mechanical equipment: U-shaped purlins are commonly used for supporting and fixing mechanical equipment, such as workbenches, conveyor belts, etc. They can provide a stable working platform and support frame, improving work efficiency.

Installation and construction of purlins

Whether it is C-shaped purlins, Z-shaped purlins, or several types of purlins, their installation and construction require rigorous craftsmanship and professional skills. During the installation process, it is necessary to strictly follow the design drawings and requirements to ensure the accurate installation position, direction, and angle of the purlins. At the same time, attention should be paid to the fixing method of the purlins, such as using bolts, rivets, etc., to ensure a firm connection of the purlins.

During the construction process, it is necessary to consider the bearing capacity and bending resistance of the purlins, and choose appropriate support and fixing methods. At the same time, attention should be paid to the protection of purlins to prevent a decrease in their load-bearing capacity due to corrosion, wear, and other reasons.

Online Service

Online Service