As a first level agent of Panzhihua Iron and Steel's zinc aluminum magnesium color coated coils, Dianchang has around 3000 tons of stock in stock in its warehouse, with complete specifications. Special colors can be customized according to customer requirements.

Introduction to Pangang Vanadium Company:

Panzhihua Steel Vanadium Co., Ltd. of Pangang Group is one of the founding enterprises and core enterprises in the steel industry of Pangang Group. Founded in 1965, it is the first domestic and world-class steel rail production enterprise, and an important plate production enterprise in the western region.

Exterior Scene of Pangang Vanadium Company

Exterior Scene of Pangang Vanadium Company

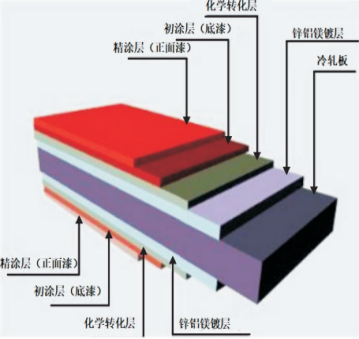

Hot dip galvanized aluminum magnesium substrate

The zinc aluminum magnesium coating is mainly composed of ternary alloys of Zn, Al, and Mg, which have been widely used in the construction and home appliance industries due to their high planar corrosion resistance and high notch corrosion resistance; In the 1960s, the United States Inland Steel Company began experimental development of hot-dip galvanized aluminum magnesium products. In the 1990s, Japan's Nippon Steel and Nippon Steel achieved commercial production of zinc aluminum magnesium coated steel plates; Pangang achieved mass production of zinc aluminum magnesium steel plates in 2019.

The corrosion resistance of the flat part of the zinc aluminum magnesium coating can reach 4-8 times that of ordinary galvanized substrates; At the same time, the zinc aluminum magnesium coating has a certain degree of self-healing. When the coating is scratched or has a cut, the magnesium dissolved from the coating can generate a dense oxide film containing magnesium on the cut surface, covering the steel substrate exposed at the scratched or cut site, thereby improving its corrosion resistance. Therefore, it has a good protective ability for the cut edges, welding parts, and areas where the coating is damaged due to severe deformation, greatly improving the overall corrosion resistance of the product.

The zinc aluminum magnesium coating has excellent processing performance and can be rolled and processed into various plate types, such as screw penetration plates, angle bending plates, corrugated plates, etc. It has good processing properties such as bending, welding, and bonding. Can be used as raw materials for steel structure building enclosure systems, such as roofs, walls, ceilings, rolling shutter doors, etc. of industrial plants, airports, sports venues, exhibition halls, or residential buildings.

Introduction to color coated board:

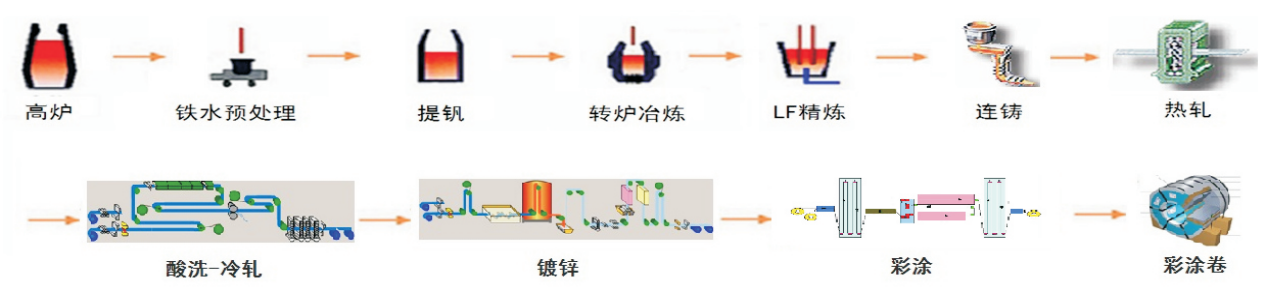

Schematic diagram of the entire process:

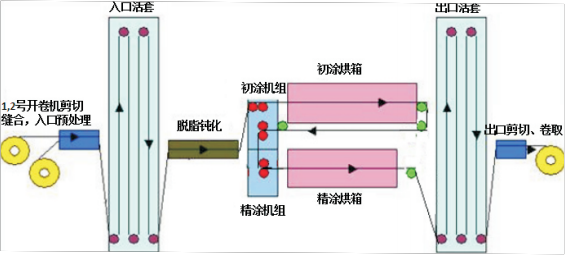

Schematic diagram of color coating process:

Scope of Supply:

项目 | 特点 |

尺寸 | 厚度0.4~ 0.8mm 、宽度900~1250mm |

内径、卷重 | 内径 φ508mm 、卷重2-10 吨 |

涂料种类 | 普通聚酯PE、硅改性聚酯 S MP、高耐候聚酯HD P、聚偏氟 乙烯 PV DF |

涂层结构 | 正面二层 ,反面一层 2/1;正面二层 ,反面二层2/2 |

膜层厚度 | 底漆 ≥5、面漆 ≥15 、背漆 ≥5 |

总膜厚: ≥25 | |

锌层重量 | 60-275g |

Brand, purpose, mechanical properties and execution standards:

力学性能 | |||||||

基板类型 | 牌号 | 用途 | 屈服强度 | 抗拉强度 | 断后伸长率 | r90 | n90 |

锌铝镁 | TDX51D+ZM | 一般用 | 270~500 | ≥26 | — | — | |

TDX52D+ZM | 冲压用 | 140~300° | 270~420 | ≥30 | — | — | |

TDX53D+ZM | 深冲用 | 140~260 | 270~380 | ≥34 | ≥1.4 | ≥0.17 | |

TDX54D+ZM | 超深冲用 | 140~220 | 270~350 | ≥38 | ≥1.7 | ≥0.19 | |

TS280GD+ZM | 结 构 用 | ≥280 | 360~500 | ≥18 | — | — | |

TS320GD+ZM | ≥320 | 390~530 | ≥17 | — | — | ||

TS350GD+ZM | ≥350 | 420~560 | ≥16 | — | — | ||

执行标准:GB/T 12754-2019 | |||||||

Allowable size deviation:

厚度允许偏差/mm | |||

公称厚度/mm | 普通精度 | 高级精度 | 宽度允许偏差/mm |

≤0.40 | ±0.03 | ±0.025 | +5 0 |

>0.40 ~0.60 | ±0.04 | ±0.035 | |

>0.60 ~0.80 | ±0.05 | ±0.040 | |

Note: The thickness deviation within a total length of 20 meters at both ends of the steel strip is allowed to be 50% greater than the specified value in the table.

Conventional performance of coating:

光泽60。(%) | 180°弯曲 | 耐盐雾 | 耐溶剂性 (次) | |||||

涂料类型 | 铅笔硬度 | 高 | 中 | 低 | ≤0.75mm | 反 向冲击(J) | (h) | 正面 |

聚酯面漆 | ≥H | >70 | 40~70 | <40 | ≤5T | ≥9 | ≥480 | ≥100 |

硅改性聚酯面漆 | ≥F | >70 | 40~70 | <40 | ≤5T | ≥9 | ≥600 | ≥100 |

高耐候聚酯面漆 | ≥HB | >70 | 40~70 | <40 | ≤5T | ≥9 | ≥720 | ≥100 |

聚偏氟 乙烯面漆 | ≥HB | - | 40~70 | <40 | ≤5T | ≥9 | ≥960 | ≥100 |

环氧背漆 | ≥H | - | 40~70 | 40 | ≤5T | ≥7 | -- | ≥50 |

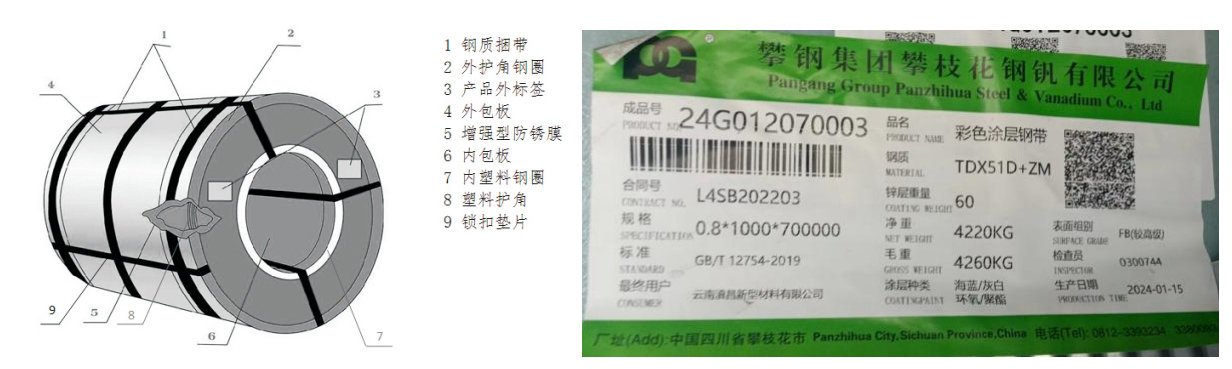

Product identification:

Anti counterfeiting code: sprayed on the lower surface of the steel strip for product identification and anti-counterfeiting.

Usage guide:

Transportation and storage

Color coated plates should be stored in a dry and clean environment, avoiding corrosion by corrosive media. The storage floor should be flat and free of foreign objects to prevent steel coils from being damaged.

During transportation, loading and unloading of color coated plates, attention should be paid to strengthening protection to avoid damage to steel coils.

The coating and mechanical properties of color coated boards will decrease with prolonged storage time. It is recommended that users process and use them within 6 months from the date of production. To avoid a decrease in the performance of the coating during low-temperature processing, the forming process of color coated plates should be carried out at room temperature.

Avoid direct exposure of the back paint to sunlight.

machining

During processing, the processing equipment and surface should be kept clean and tidy to prevent foreign objects from damaging the painted surface.

When using color coated boards for the production of sandwich panels, considering the compatibility of the user's adhesive and production process with the color coated boards, it is recommended to conduct small-scale experiments first.

Product packaging:

The use of enhanced product protection measures can effectively prevent and improve compression and collision during product transportation, storage, and use

Defects such as collision, abrasion, corrosion, etc.

Application area:

Zinc aluminum magnesium color coated coils exhibit excellent corrosion resistance in various harsh environments due to their unique coating composition and structure. The specific environment includes:

1. High humidity environment: In areas or environments with high humidity, it can effectively resist corrosion caused by humidity.

2. Industrial environment: Industrial areas have strong corrosiveness to materials due to the emissions of exhaust gases, smoke, and chemicals. Zinc aluminum magnesium color coated coils exhibit good corrosion resistance in such environments.

3. Marine environment: Areas near the ocean are highly corrosive to materials due to the influence of salt spray. Suitable for marine engineering and coastal construction, as it can effectively resist the corrosion of seawater.

4. Environmental pollution: In areas with severe pollution, such as near chemical factories, it can resist corrosion caused by pollutants.

5. Extreme weather conditions: Whether in high temperature and humidity or extremely cold regions, it can maintain its corrosion resistance and is not easy to rust.

6. Outdoor exposure environment: Zinc aluminum magnesium color coated rolls can effectively resist the erosion of these natural factors.

Due to its excellent performance in various environments, zinc aluminum magnesium color coated coils are widely used in various fields such as construction, photovoltaic industry, transportation facilities, especially in situations that require long-term stability and durability.

Color image of the painted sample:

攀钢彩涂机组图

Online Service

Online Service